Chemical Dosing Systems and Our Dosing Tanks

What is the dosage?

Specifying the amount of substance to be included in a compound or mixture, adjusting the dosage, order.

What Are Chemical Dosing Systems?

Chemical dosing systems are a frequently used, practical and effective choice. They are known as the systems used in the dosing processes of different chemicals in many sectors. Chemical dosing systems allow different chemicals to be dosed at the desired level and automatically. Examples of these chemicals such as chlorine, corrosion preventive chemicals, pH reducers can be given. It is aimed to change fluid properties and conditions precisely. It is difficult to talk about a single use here. These systems have a great function in terms of dosing chemicals in heating or cooling systems, waste water treatment, food, cosmetics and textile industries. Chemical dosing is used in disinfection systems, flocculation systems, industrial areas, chlorine dosage processes, water and waste water facilities, swimming pools, steam boiler or cooling tower applications.

Our Dosing Tanks

Dosing is a very delicate process. It has a very important place in the chemical industry. Chemical dosing systems, on the other hand, respond to many needs in the industrial field. Different products are used in dosing systems, depending on the type of chemical or pressure. Dosing tanks are one of them.

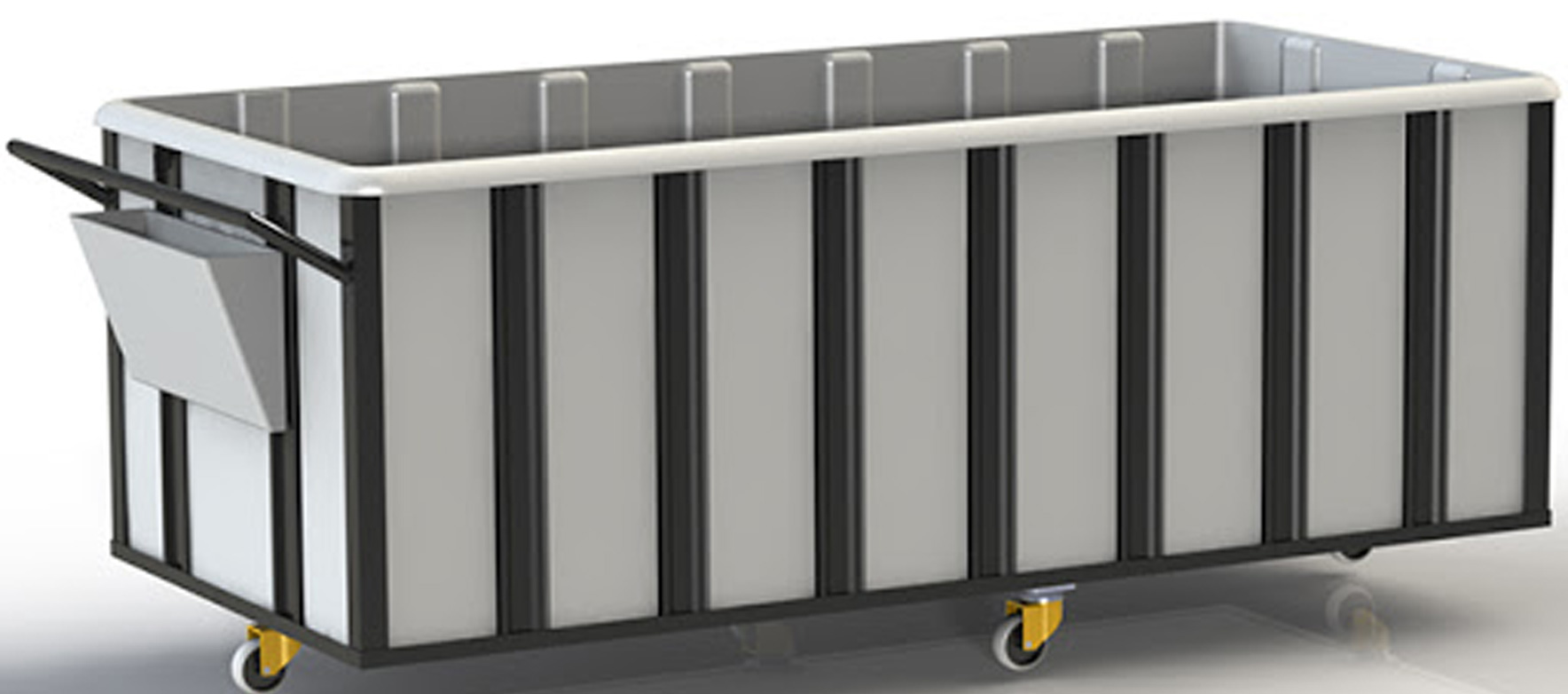

Polyethylene dosage tanks, also known as dosage measurement warehouse, dosage warehouse, chemical dosage warehouse, are among the leading plastic warehouse products that ÜNPLAST manufactures with high quality and confidence and delivers all over Turkey.

Dosage tanks, which are used especially in measuring and storing chemical products, are produced entirely from polyethylene by our company. It does not react with the substance put into the dosage tank produced with the polyethylene raw material.

Recyclable and healthy raw materials are used in all plastic dosage tanks we manufacture, or plastic dosage measurement tank models. All of our plastic products are produced with UV resistant and environmentally friendly raw materials.

All of our dosage tanks are resistant to impacts for a long time. It is specially produced against freezing in extreme cold in winter and against heating in extreme heat in summer.

Chemical dosage tanks are at the forefront with their usage advantages as well as the width of their usage areas.

Dosing tanks used in industrial establishments and factories working with chemical substances are very important for measuring the chemical substance.

One of our main features that make us the most preferred brand in the dosage tanks sector is that we use healthy raw materials, as well as the quality workmanship we apply during the production phase and the smooth appearance that results from the production. All ÜNPLAST dosage tank models have a smooth surface and are resistant to sunlight for a long time. It does not fade in color.

You can find all our production certificates and permits that express our quality in plastic product production here.

ÜNPLAST Dosing Tank Product Features:

- All of our dosage tank tanks are made of recyclable polyethylene material, approved by the Ministry of Health, TSEK quality certificate.

- Our dosage tanks are manufactured as Monoblock, there are no additional weld and rivets. This prevents leakage and product loss. (Monoblock means production in one piece.)

- All of our plastic dosage measuring tanks and dosage tank products are U.V. It is resistant to its rays. As it will not fade in color, you can safely store the stored material for a long time.

- All our plastic dosage tank models are made of impact resistant material. You can use it with peace of mind for a long time.

- All our plastic tanks can be easily cleaned even with just water. The cleaning of our warehouses should be at least 6 months to 1 year.

- It is resistant up to - 5 / + 65 degrees.

You can find all our other ÜNPLAST products here.